introduction

As a follow up of the soliton splash i wanted to make a sculpture starting with the movie of the splash. Outlines were handtraced from chosen set of videostills and various form experiments were made to find a proper shape. The wooden waves from the beach experiment were succesfull and this would be the starting point.

Execution:

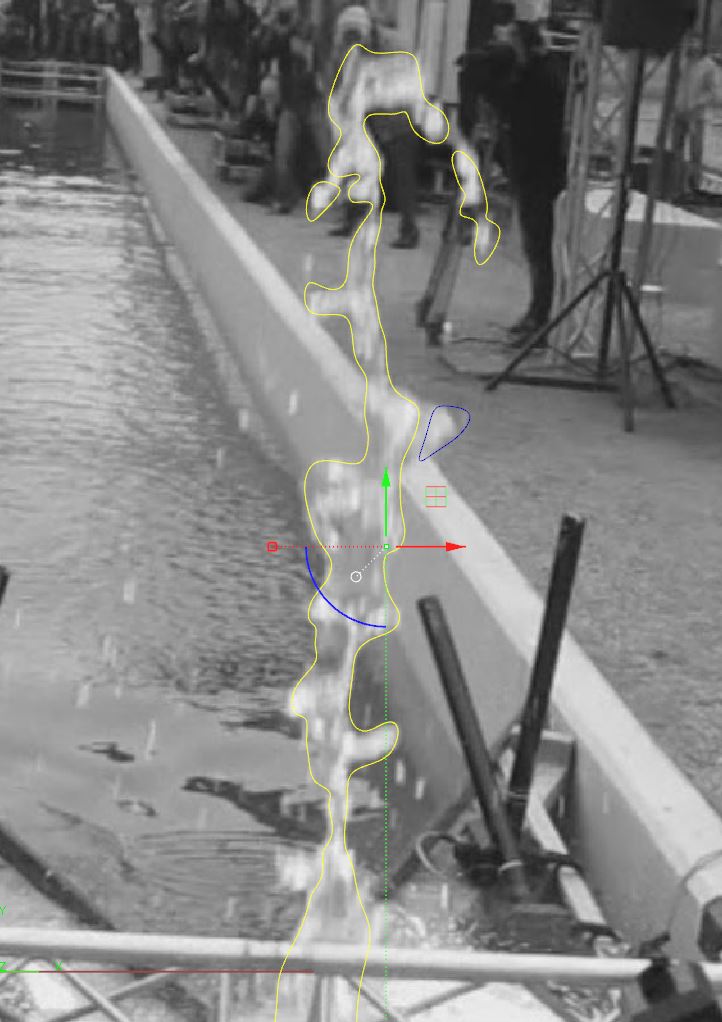

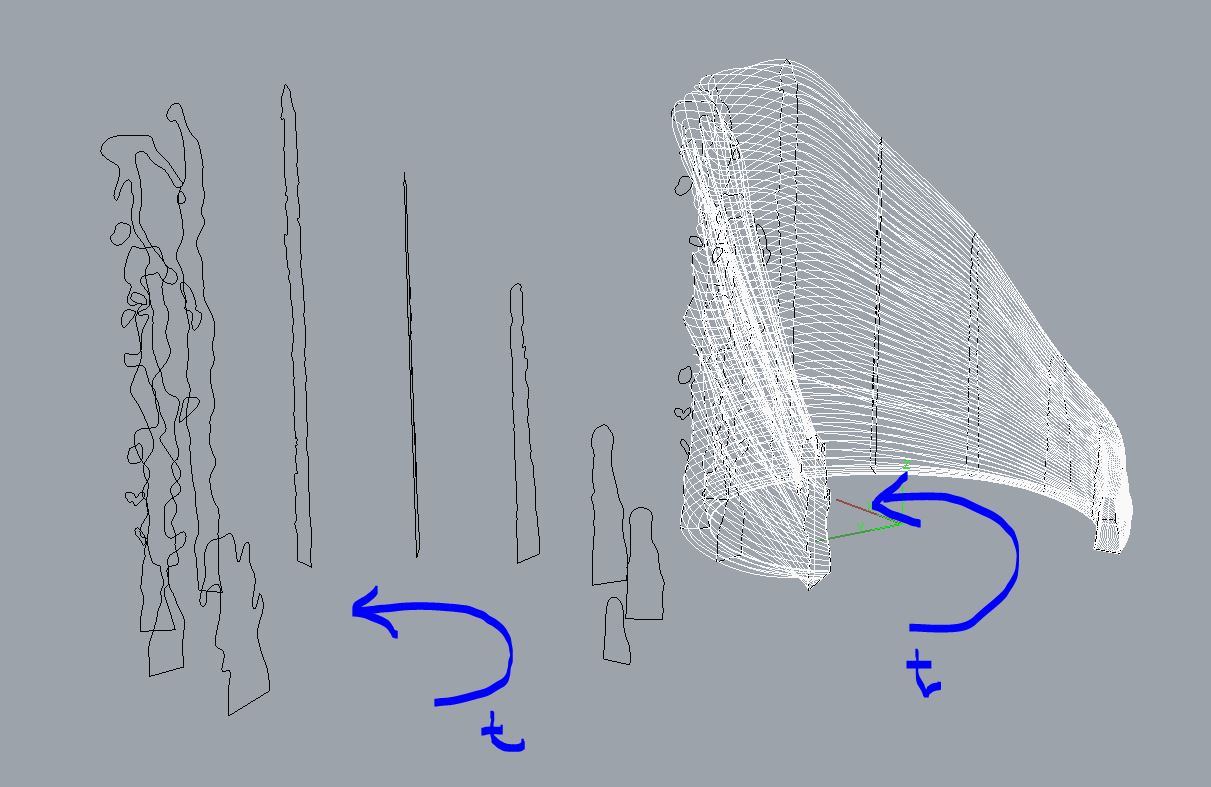

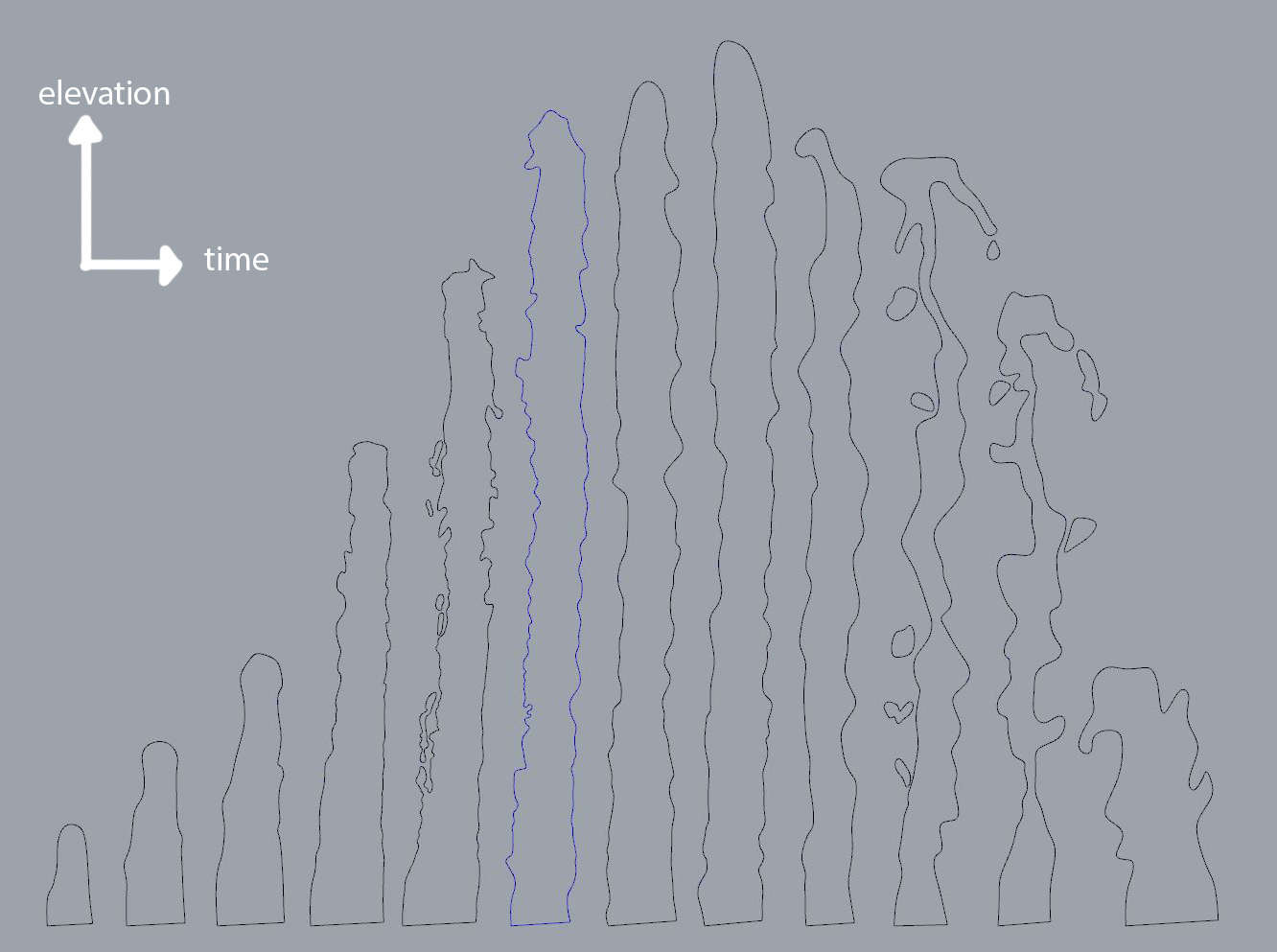

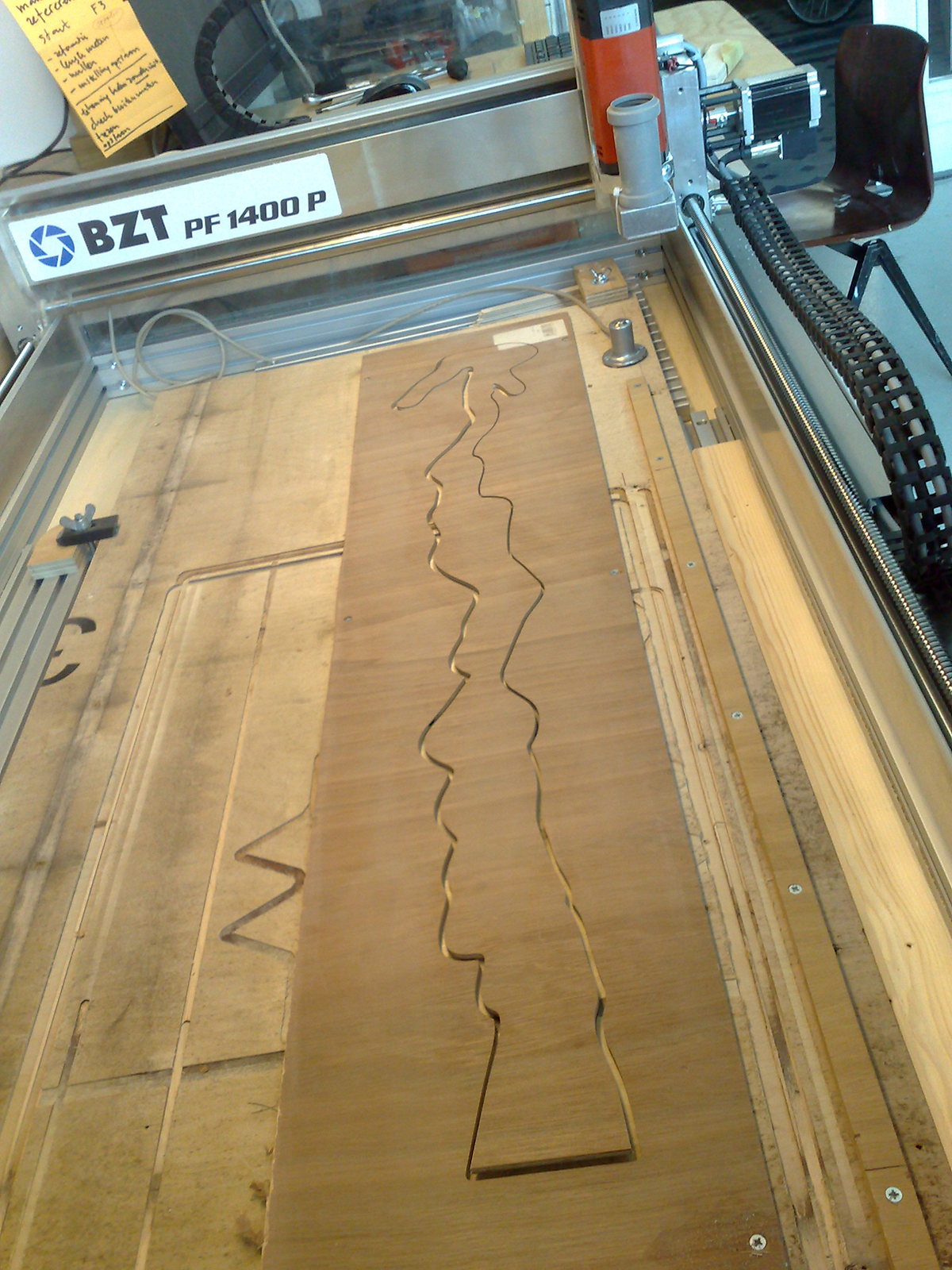

The original images (video stills) were used as a background in the cad program Rhino. Automatic tracing was impossible because of the cluttered background. Tracing was done by hand for a selected amount of pictures and these contours were aligned as good as possible. However, the splash-shapes were much harder to trace than the waves due to the irregular form of a splash. This did not work out well, for the moment being. This required a different approach: shapes had to be simplyfied and this is experience based ec. the mental image how a splash looks will interfere with the actual (but non tracable) shape. A second problem was the long interval: the shapes do not overlap nicely as in the waves. A solution was sought in either separate forms or making contours on top of each other in wood or acrylic. Also a 3D print of the contours was made. The resulting shape needed to be changed to be more attractive as well as informative. The result was a radial approach instead of a linear one and this worked out much better.

A model was made out foam (which is easy to model), then in wood (one with the splashes next to each other, one as a block of wood with two chosen splashes cut out in the front and the back. A plexiglass sheet was cut with the outlines and sidelit, this worked well and finally the two chosen outlines were realized in steel on a scale of about one to three and presented as sculptures.

The whole process appaered to be an experiment and investigation about what can be done with a given scientific shape and the most unexpected results were the acrylic sheets and the molten foam which reminds oft the fluidity of the original material. A casting will eventually be made from this partially molten foam to show the surprise and delight. The steel sculptures, even though they look good, were not surprising me very much. They just performed and do their job and they were three, four nice days in the shop with welding and cutting machines. The steel literally reflects the water and the necessary simplification of the rounded shapes evokes it's fluidity very well. In a frozen image from high speed photo's, even though they look spectacular, this can get lost easily.

Future:

Better tracings will probably give a new result, which may be kind of weird looking at first. A repetition af a splash is therefore needed in a setting with a better background, a stable high speed camera and probably simultaneous shooting from various angles to reproduce the 3d structure better. Eventually a non transparant fluid can be used (dyed or muddy) to avoid misinterpretations where the surface of the fluid is.

We are at the edge of form language, experience and new images from science that still do not belong to our common knowledge. Until we get used to this new form language lasercut, rendered or 3d printed images or sculptures will remain to look strange and will be hard to connect to the common experience of water, let alone to evoke a deep emotion connected to water.

Newton Institute for mathematical science

The steel sculptures are now part of the permanent collection of the Isaac Newton Institute for mathematical science, quite an honour to have the sculpture 3 feet away from Newton's mask, probably as close as one can get to him. to the institute

tracing of videostill by hand in rhino

sequence of tracings

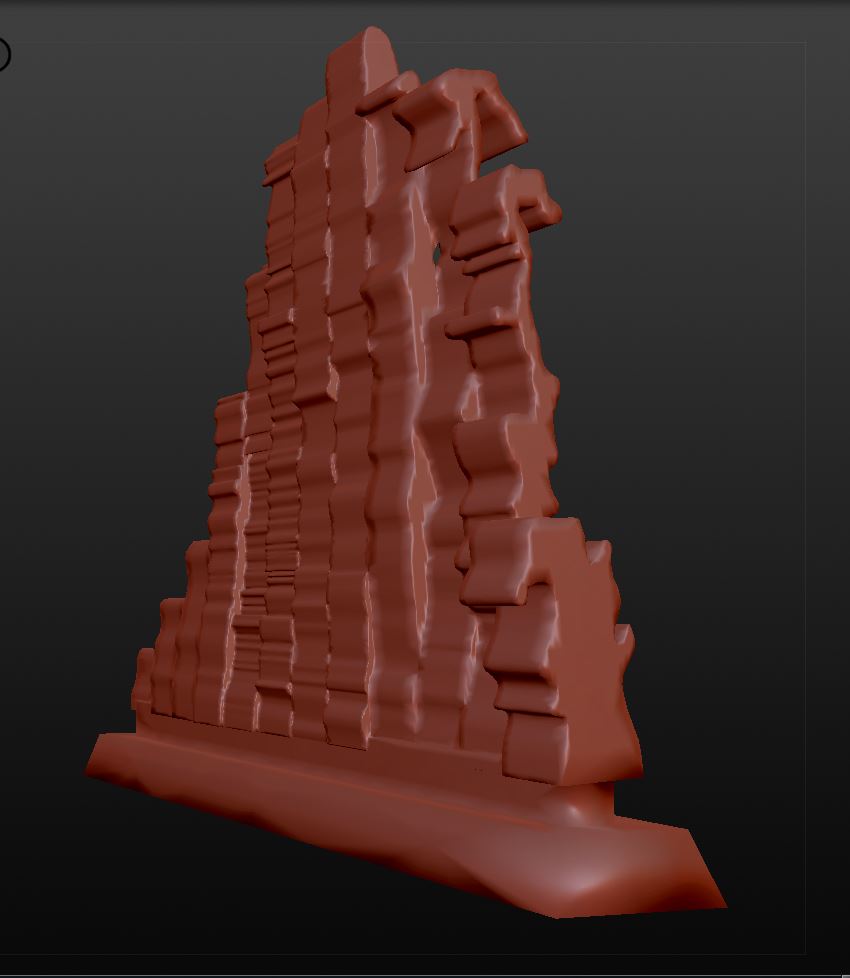

Foam scupture-study

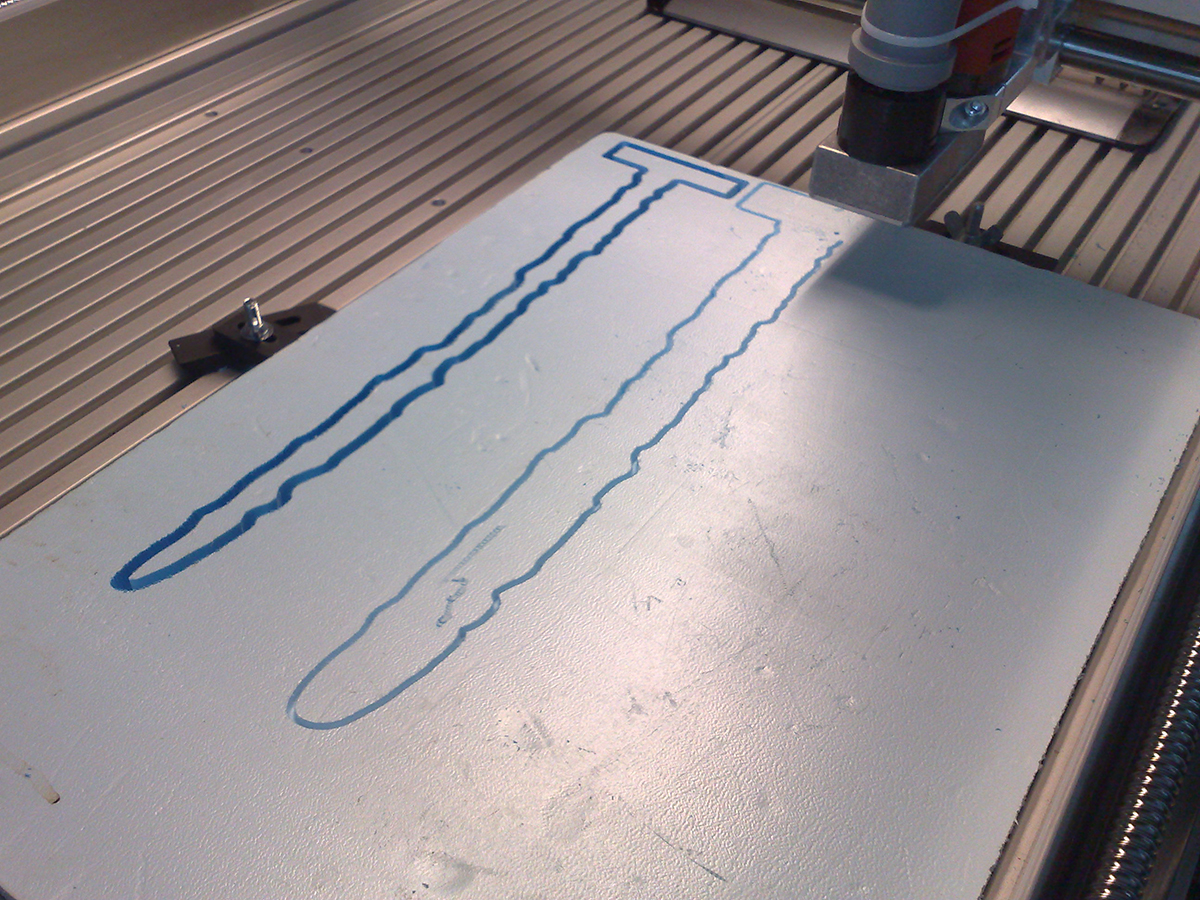

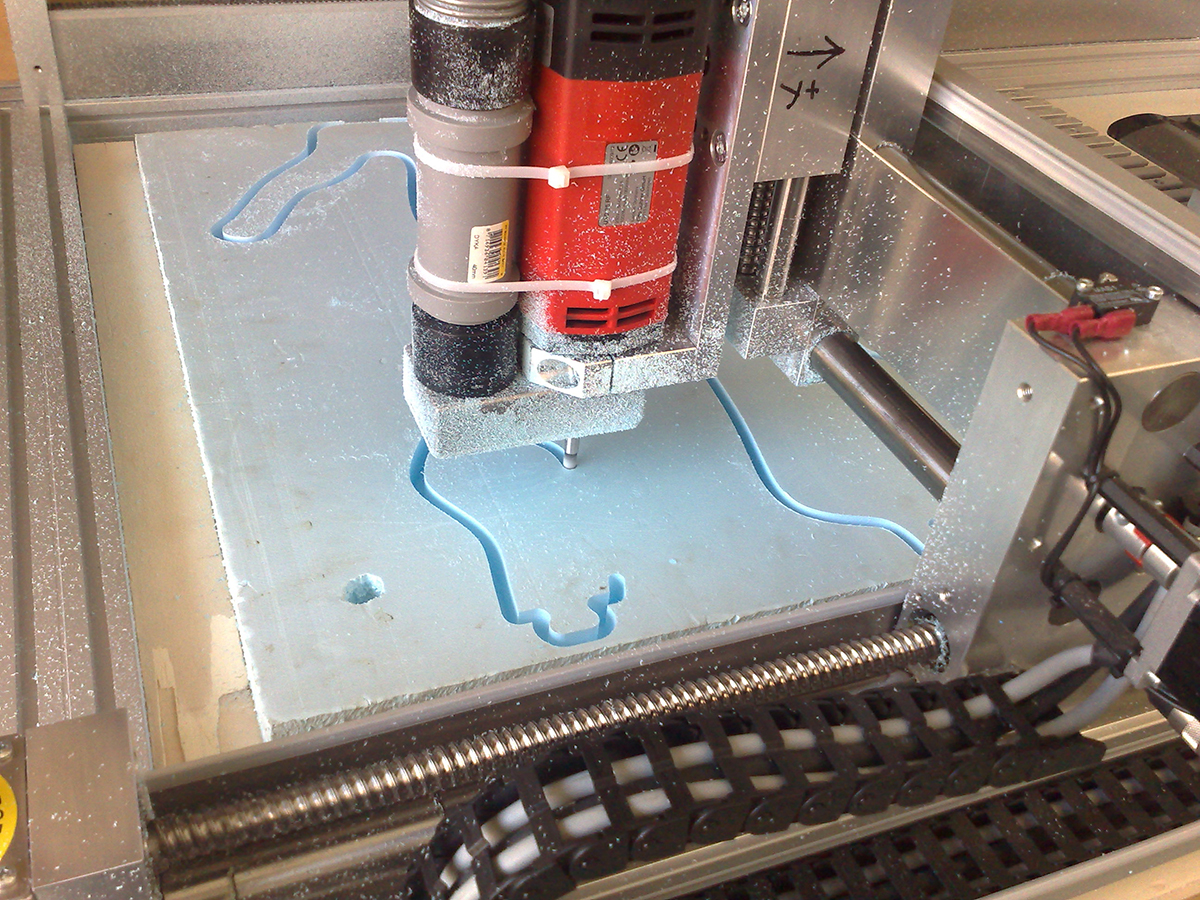

The first sculpture was made out of foam (five cm thick roofmate). These were also my first experiences with the new router in my shop and i made some errors by running the router too fast. The chisel heated up too much and foam was melted. The form that resulted was a nice surprise. Later i managed the speeds better and clean cuts resulted. A bigger sculpture was made with interlocking parts.

A wooden splash was cut with the router as well, and also a acrylic sheet. The negative shape in wood enabled me to keep the separated waterdrops together with the solid core. This could not be achieved with the positive foam sculpture. Finally A sheet was cut with all outlines in various depths. This also worked well.

the steel sculpture

For a lecture about the article for Bridges 2013 We (Onno, Valerie and me) wanted to show some more serious sculptural approach. A steel sculpture would be a great thing located on the original place of the solitonsplash (the educational square at Twente University). This was too ambitious to construct in just a couple of weeks, so two smaller steel sculptures were made that had sculptural qualities in themselves.

3D prints and rendered visualisations

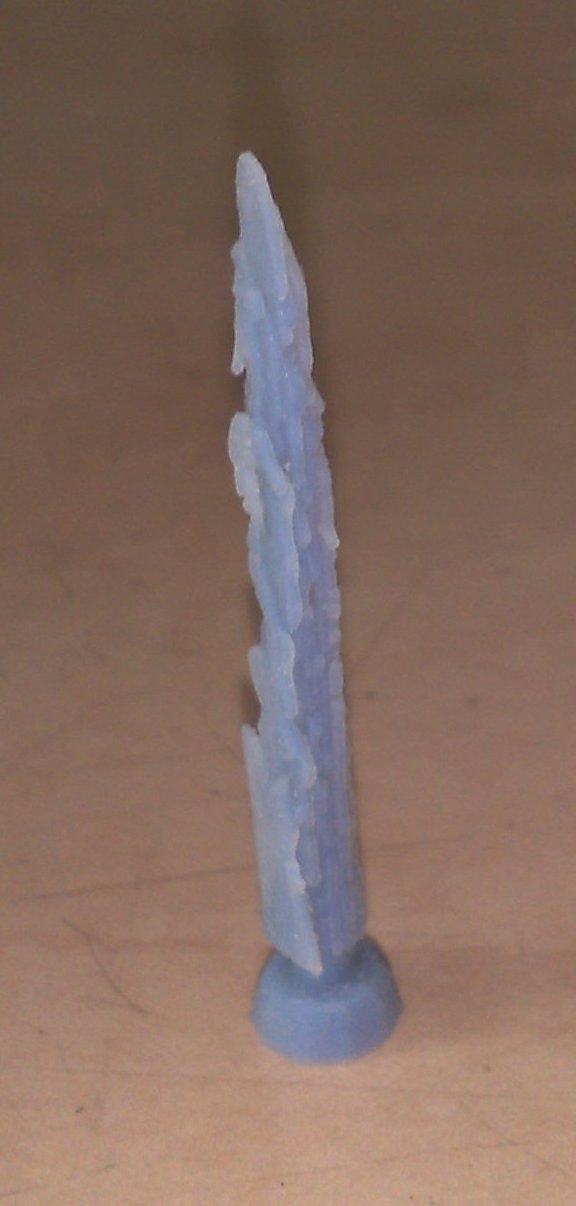

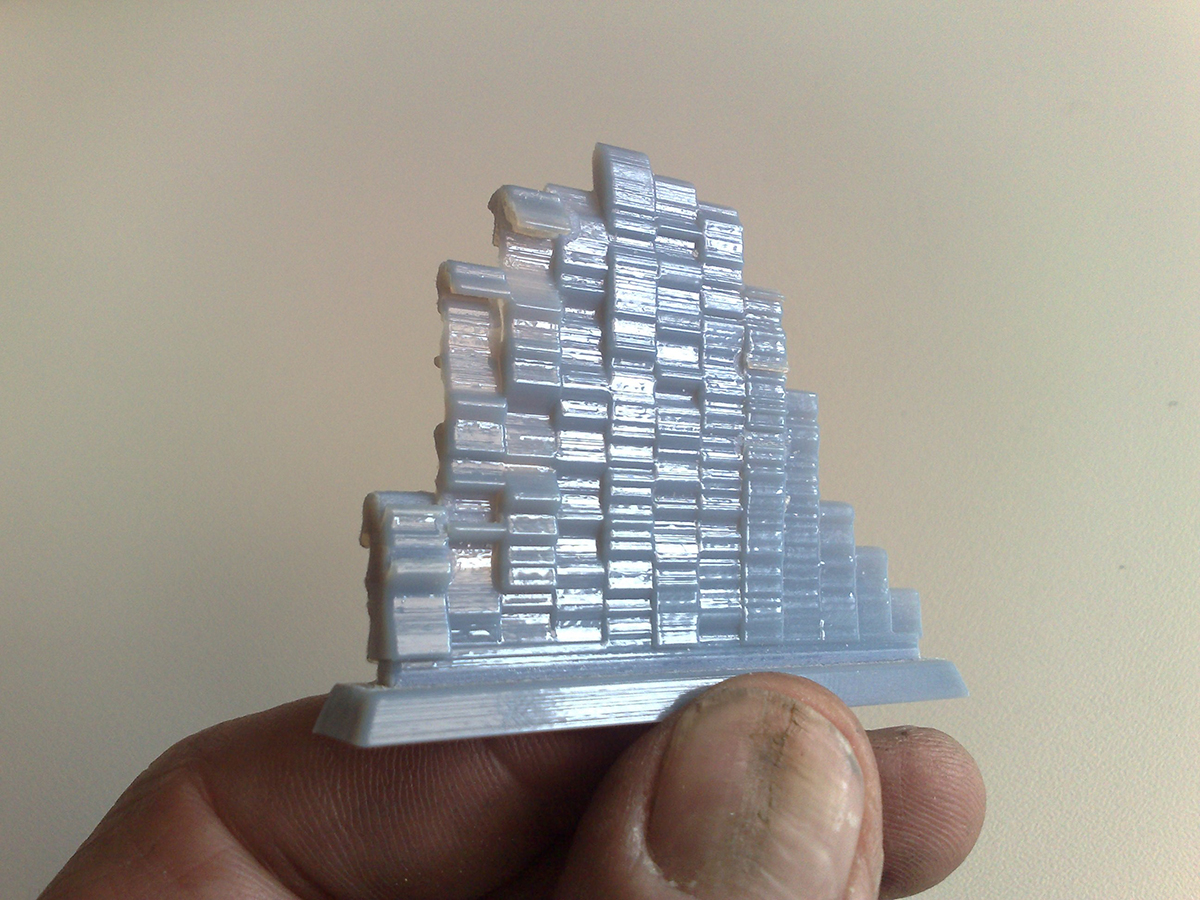

After making these sculptures a 3D print was made in the same way as the bore soliton waves. The first result however was not very interesting. The next step was enlarging the thickness of the slides and the final, much more intriguing one, was the radial approach of time instead of the formerly tried lineair one. A radial shape had been tried in earlier in the proces but rejected because of lack of sculptural qualities. This version could be evaluated well enough with a visualisation with a cad program (rhino3D). This structure would be hard to realise in traditional welding. A 3D printer provides the opportunity to make an exact copy of this complex design and offers a usefull instrument for further reseach on visualisations of flow of fluids.

3D print (Objet material jet printer, size about 40 mm tall). This object is not very informative.

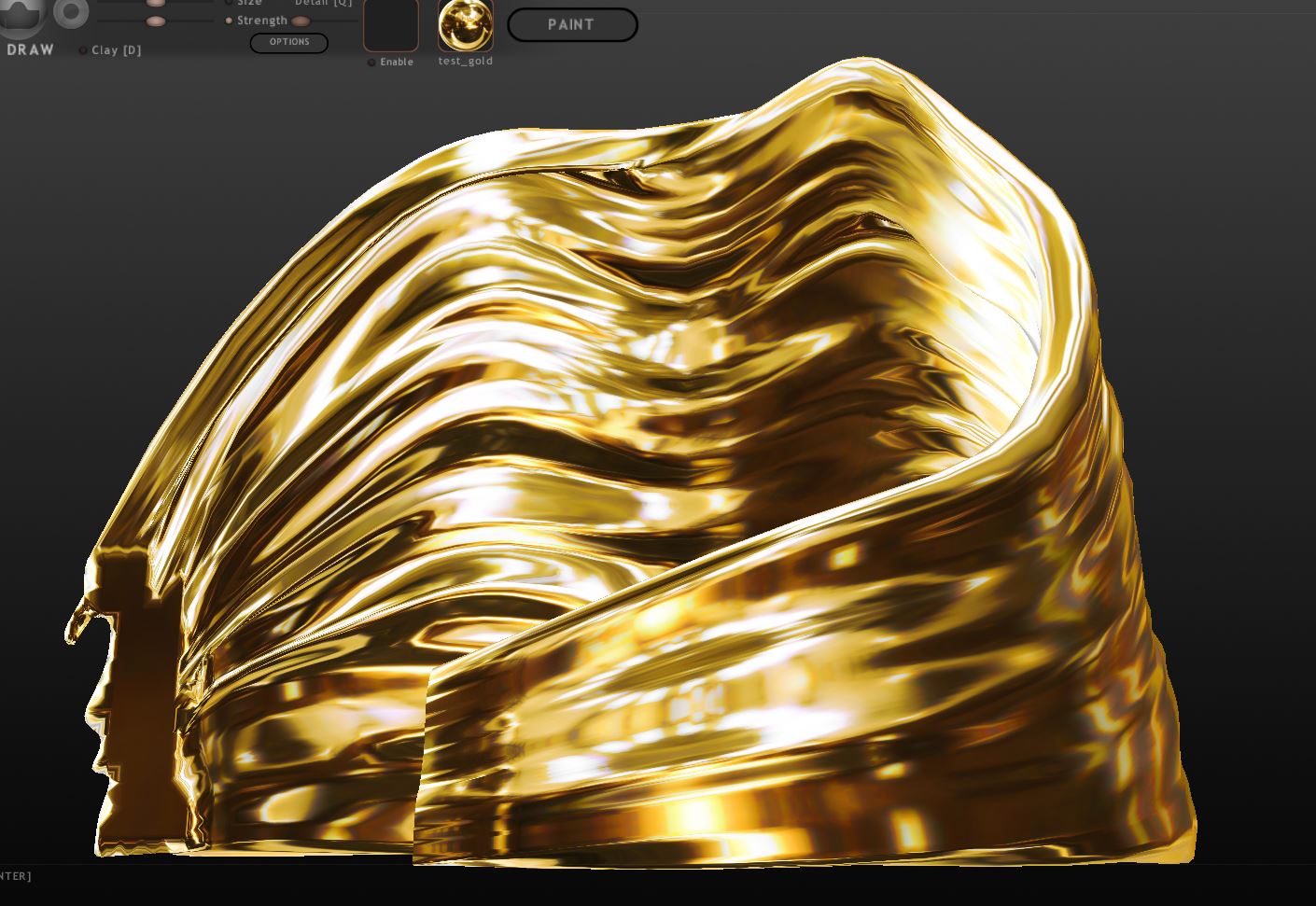

The same object, but with thicker layers than in previous print (Sculptris rendering) , the curves are much better visible

3D print of all splash profiles, lineair time sequence

Preparing contourcurves for lofting, time is now radial instead of lineair.

Rendering (Sculptris) of lofted splash curves. This structure will be printed on the Objet printer and eventually in a metal SLS (lasersintering) printer. This sculpture is choosen because the good evocation of water associations. The accuracy of the curves and therefore the use as scientific visualisation is limited because the hand tracing of suboptimal reordings. With a better recording (high speed, high resolution tracing, even background) a more accurate visualisation will be possible.

We made a presentation for the Bridges festival (bridges 2013 Enschede), you can watch this presentation (12 MB). It is an elaboration of previous slides and als contains background of the wave models that inspired the visualisation.